Sparkle is a thought experiment which imagines all the advantages of additive manufacturing over traditional manufacturing. The ecosystem highlights the user-friendly potential of lighting by emphasizing modularity, serviceability and easy end of life disassembly.

Watch the Video

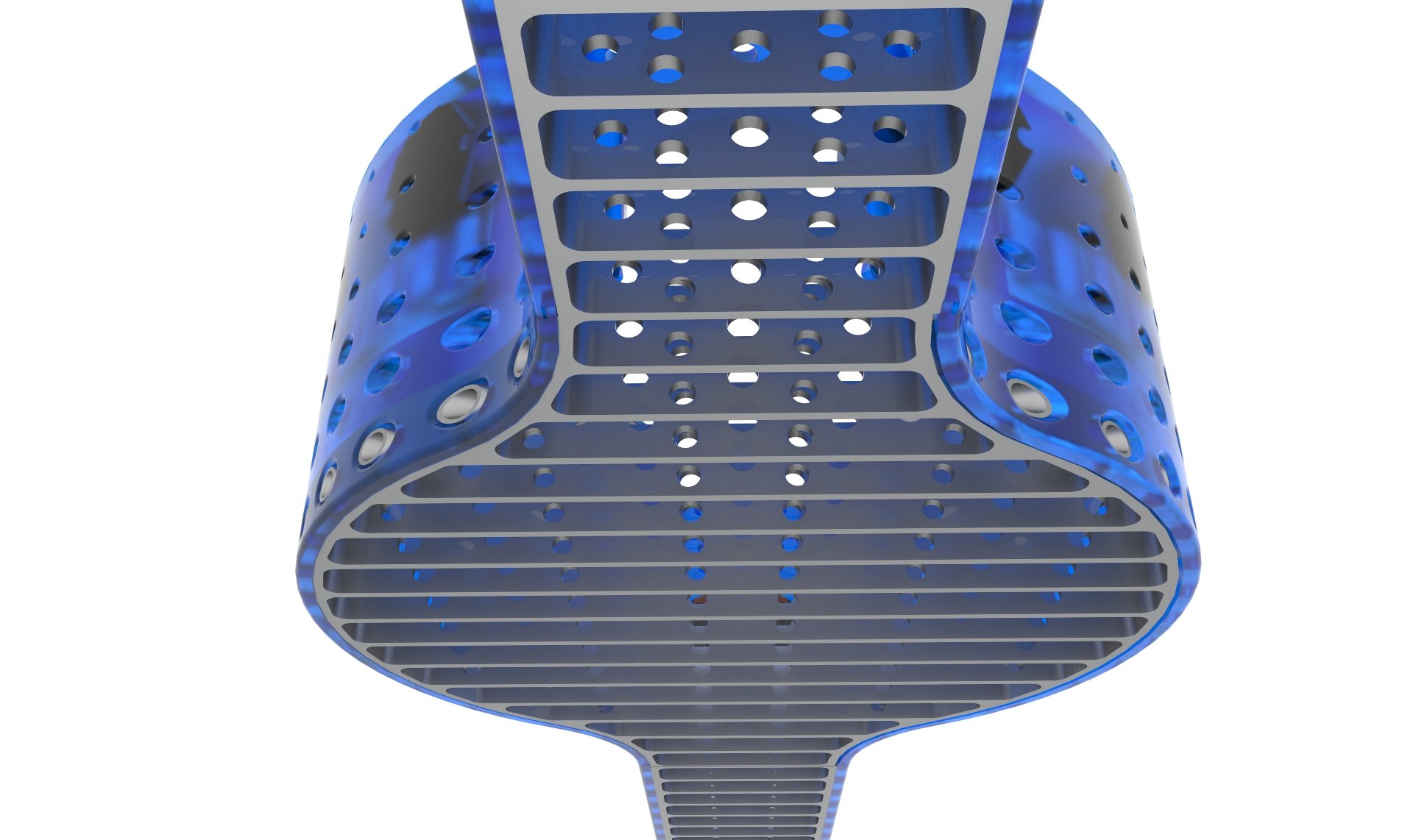

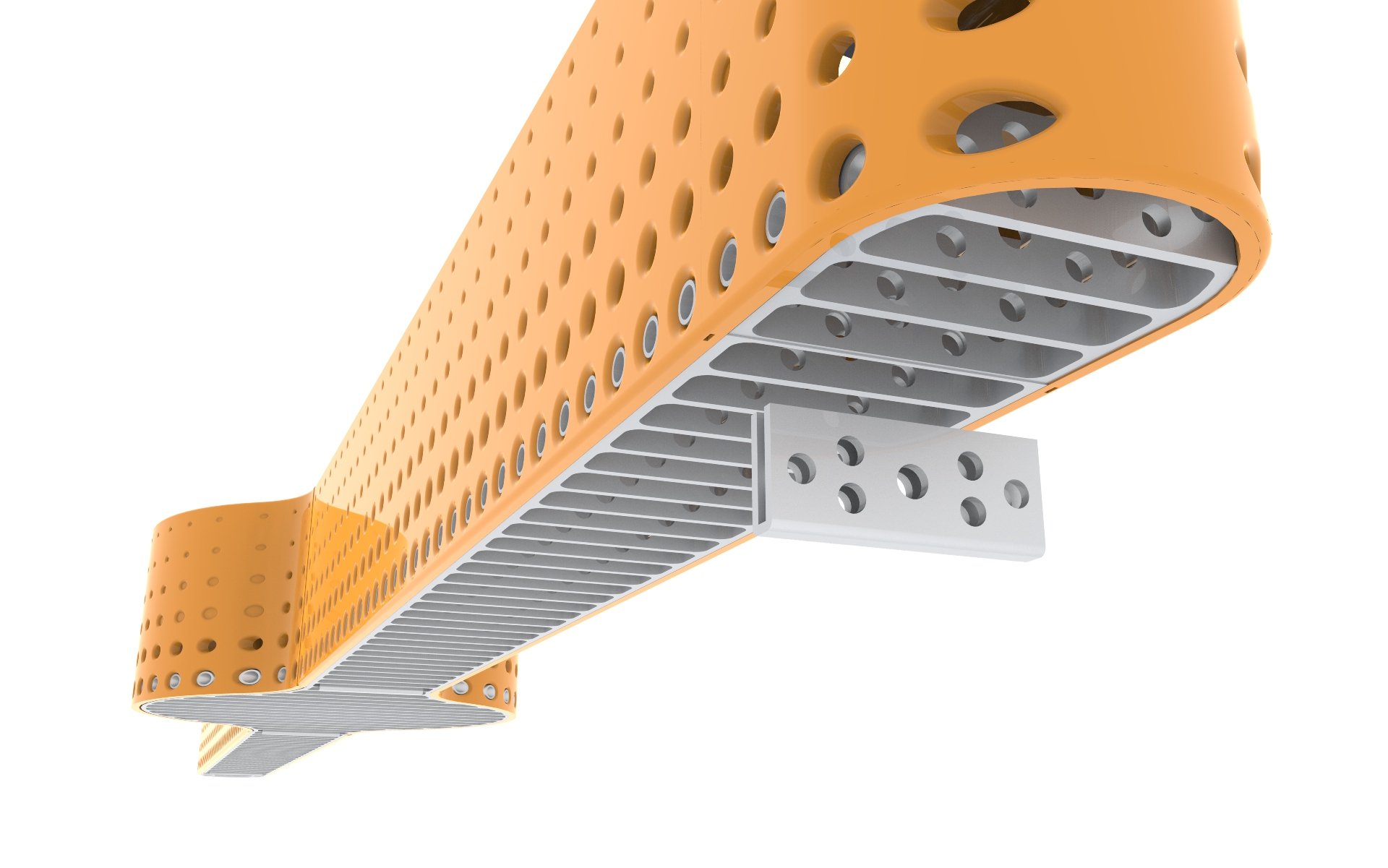

What’s with all the Perforations?

Holes are a feature that would either be impossible or prohibitively expensive with traditional manufacturing. Most luminaires are static—meaning there is no airflow, and heat build-up can compromise the lifetime of the LED. By providing holes throughout, we give the LEDs room to breath.

Holes also mean less material used and less time and energy used in the printing of the part.

Perhaps what we like most is that holes allow easy ways to attach accessories, connect sections and provide a template for future advancements.

Why Is it called Sparkle?

Sparkle is a term that describes a light source that is bright but not glare. It can increase the perception of brightness in a room.

We developed the sparkle louver because traditional louvers compromise the light output so much. By using thinner fins and creating perforations, fixture efficiency increased dramatically.

An additional benefit was that looking at the luminaire from below reminded us of the forest canopy. This biophilic effect so enamored us, we named the luminaire after it.

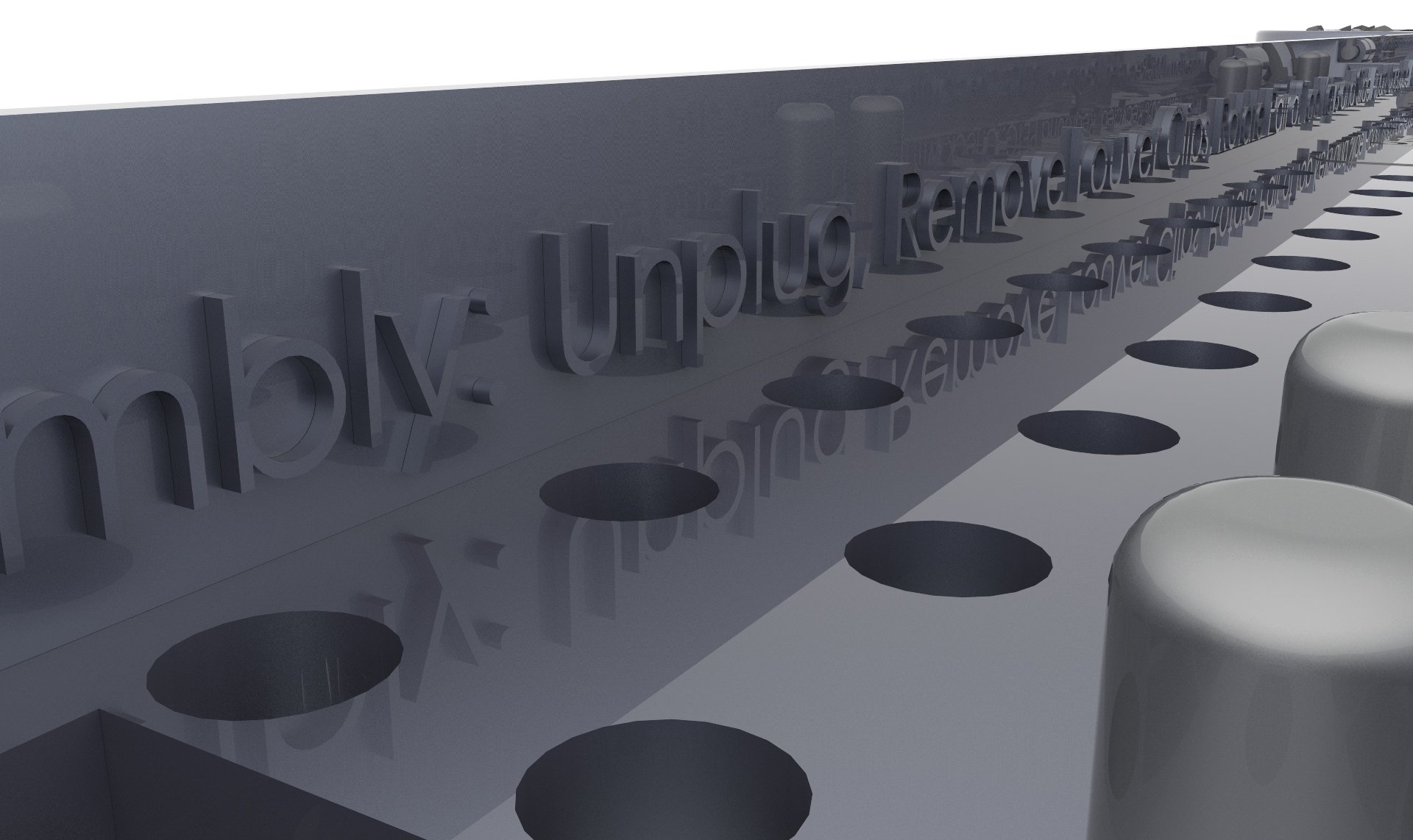

Tool-Less Assembly

For modifications, field servicing or End-of-Life disassembly, not having to use a tool is a great benefit.

Our louver clips and dumb bell pins allow for seam-less connectivity

It creates operational advantages for the manufacturer as well with easier cell logistics and a greatly reduced BOM

Medallion System

We wanted to have a QR code on our luminaire for easy customer access to information. What about the long lifetimes of LED Luminaires however? What if QR codes become obsolete? This made us develop the medallion system—a removable piece that is field replaceable. Different medallions can be used to communicate different messages for different jurisdictions.

We’ve even have a place for an on-board LED replacement from the same batch in order to ensure continuity of light quality if you ever need a reason to replace.

Replaceable, Individual LED Modules

LEDs have come a long way. Current long boards with dozens of LEDs on them are holdovers from a time when LED output was restricted. These days a single LED can put out 300 lumens. Given that Sparkle doesn’t use a diffuser, we could replace the strip with a few stand-alone LED module. This greatly reduces the materials, and single star boards are recyclable where the long strips are not. It also makes it easy to field replace LEDs with the spare provided.

End of Life

Disassembly Instruction built right into the luminaire.

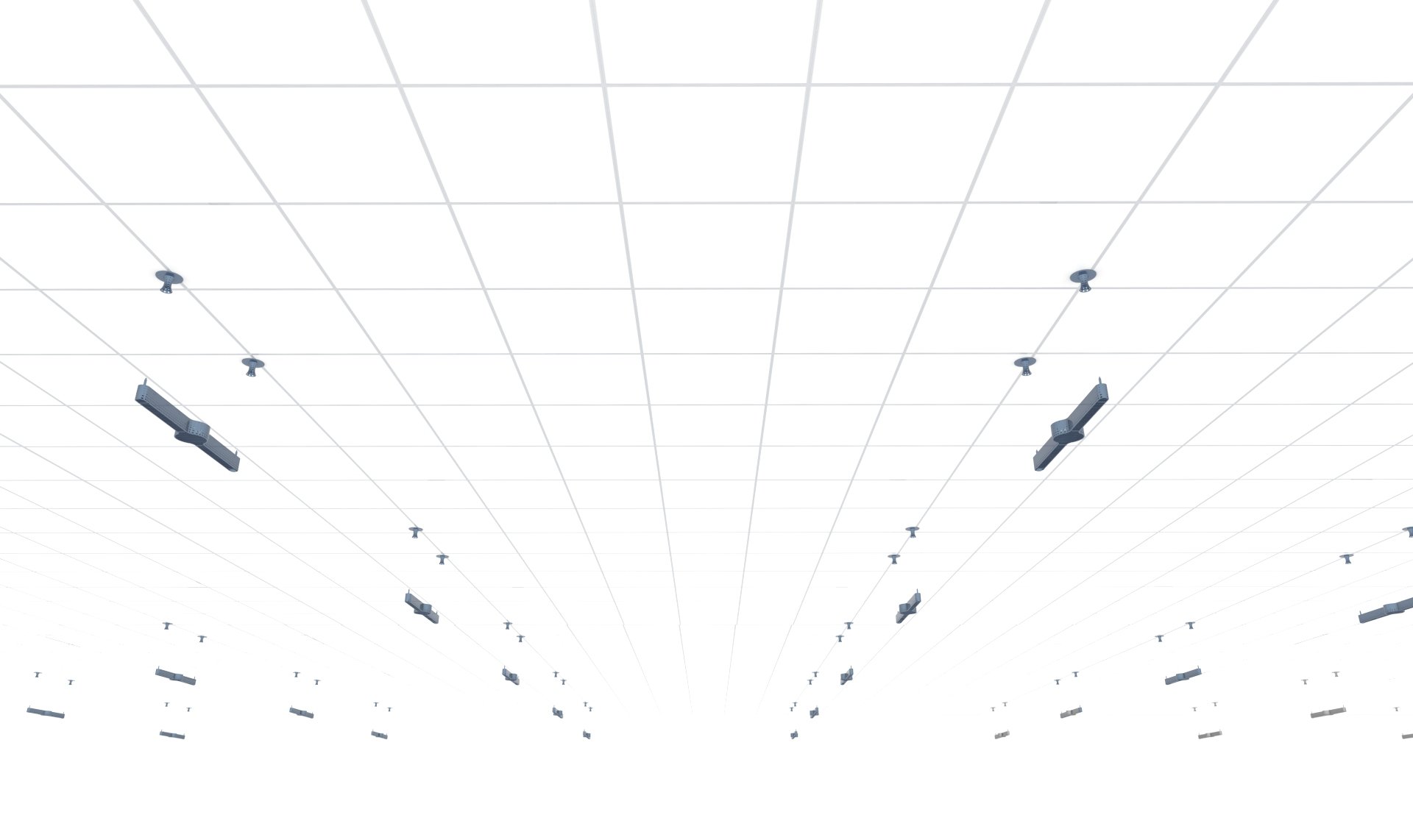

Lateral Symmetry

Thanks to a powerful omnidirectional uplight, stand-alone configurations are able to greatly increase spacing between luminaires, which dramatically decreases the power density in commercial spaces. Fewer fixtures means less cost and reduced installation.